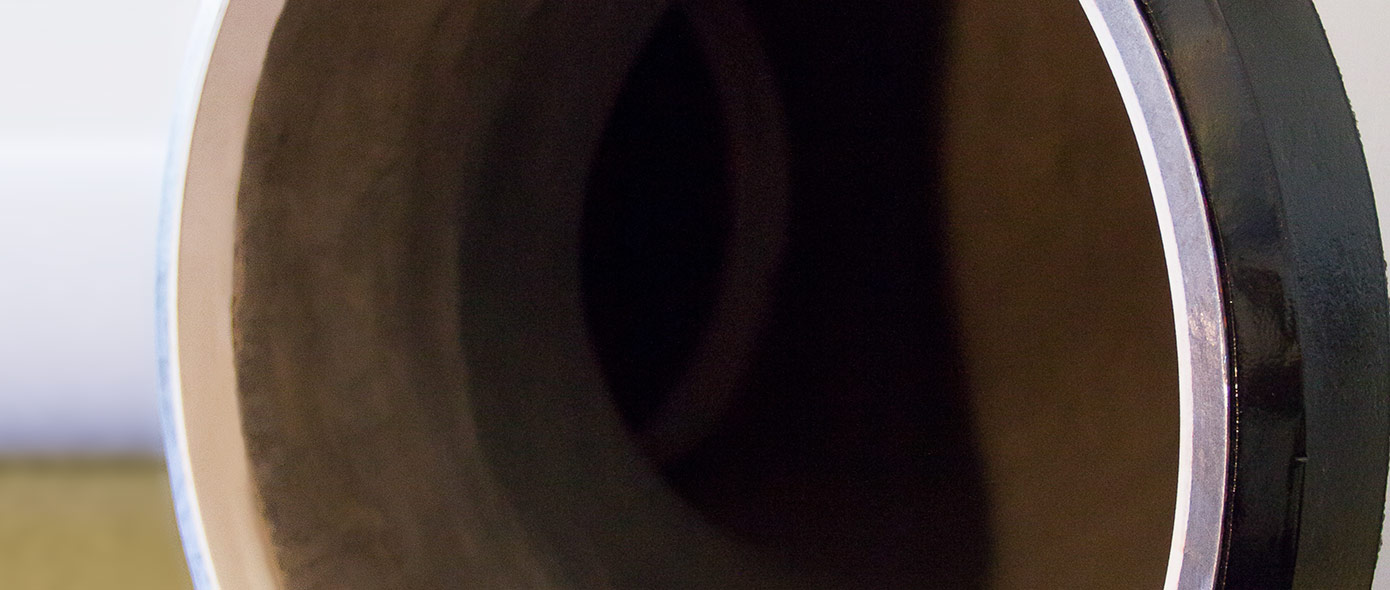

Joint Lock Ring

Features/Benefits

- Allows for full penetration joint welding with no internal cement contamination in the weld zone.

- Allows for mechanical and nondestructive testing of the finished weld.

- Allows for a reduction in pipe wall thickness and weld time over partial joint penetration designs.

- Replaces a challenged industry standard for joining cement lined pipe.

- Accomplished a permanent inside pipe shoulder for cement lining containment and protection that is out of the weld

- zone.

- Joint Lock Rings can be factory installed in all straight pipe and loose fittings to be butt welded in the field.

- Joint Lock Rings (loose) can be easily installed in the field after cutting and beveling the pipe.

- Shop quality internal cement lining patches can be accomplished by installation crews in all “cut to fit” field

- joint applications.

- Some designs of the joint lock ring utilize an o-ring gasket that provides a secondary pressure seal that will

- safe guard the environment in the event of a weld failure.

- Joint Lock Rings can be used with all designs of cement lining.

- The joint lock ring base material, ID coatings and o-ring seals can be engineered and adapted to meet specific

- pipe grades , various service conditions and fluid types.