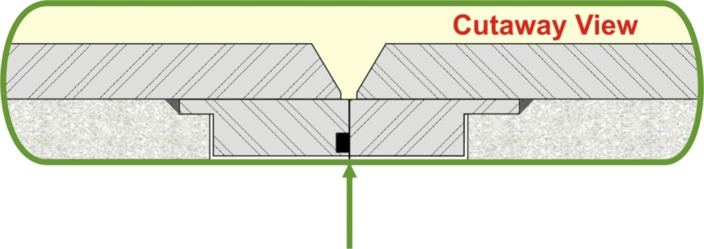

Joint Lock Ring Technology Welded ID Wall Seal Type

Field Assembly Process – Joining Full Length Pipe Sections Using Lock Rings

The second half of the Joint Assembly Tool is attached to the 2nd section of pipe.

The 4 bolts are then tightened to draw the two pipe sections together, compressing the O-Ring between the two Lock Rings.

The pipe is tack welded in four places to secure the joint alignment and maintain O-Ring compression.

The tools are removed and the full penetration joint weld is completed.

One section of pipe is set on jack stands or dunnage.

Half of the Joint Assembly Tool is attached to the end of pipe.

A second section of pipe is set on jack stands or dunnage with the pipe alignment plate properly positioning the two pipe ends for fit up.

The field assembly process is now complete.

The following demonstration will take us through the

field assembly process used for joining 2 full length pipe sections utilizing preassembled Joint Lock Rings.

WELD LOCK JOINT

40' PIPESECTION #140' PIPESECTION #2